Leading Asbestos Abatement Tools For Safe and Effective Removal Processes

Browse essential equipment designed to support thorough asbestos removal with safety and precision at the forefront.

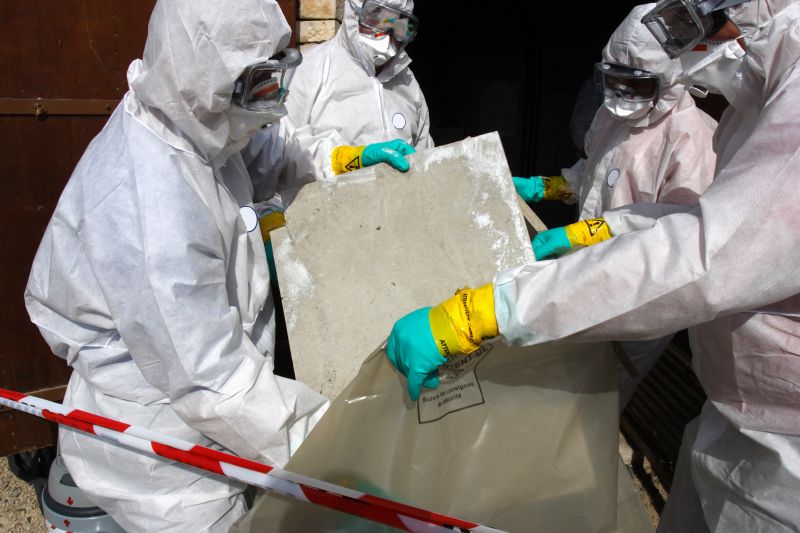

Handling asbestos abatement requires specialized products designed to ensure safety and efficiency during removal and containment processes. Proper equipment helps minimize asbestos fiber release, protecting workers and building occupants from potential health hazards. From containment barriers to protective gear, each product plays a vital role in maintaining a controlled environment throughout the abatement process. Selecting the right tools and materials can significantly influence the safety and success of an asbestos removal project.

Handling asbestos abatement requires specialized products designed to ensure safety and efficiency during removal and containment processes. Proper equipment helps minimize asbestos fiber release, protecting workers and building occupants from potential health hazards. From containment barriers to protective gear, each product plays a vital role in maintaining a controlled environment throughout the abatement process. Selecting the right tools and materials can significantly influence the safety and success of an asbestos removal project.

Top Overall Option

Comprehensive Asbestos Abatement Kit

A complete asbestos abatement kit includes essential containment materials, protective gear, disposal bags, and decontamination supplies. Designed for versatility, it provides a comprehensive solution suitable for various project sizes. The kit emphasizes safety, ease of use, and compliance, making it a reliable choice for professionals seeking a streamlined approach to asbestos removal.

Types of Products For Asbestos Abatements

Containment Barriers and Plastic Sheeting

Heavy-duty plastic sheeting and barriers create secure containment zones to prevent fiber spread during removal activities.

Negative Air Pressure Units

These devices help maintain negative pressure within containment areas, ensuring asbestos fibers do not escape into the environment.

Personal Protective Equipment

Respirators, protective suits, gloves, and eye protection safeguard workers from asbestos exposure.

Asbestos Waste Disposal Bags

Specialized leak-proof bags designed for safe containment and transportation of asbestos waste.

Decontamination Showers and Stations

Facilities for decontaminating personnel and equipment to prevent cross-contamination.

HEPA Vacuum Cleaners

High-efficiency particulate air (HEPA) vacuums are used for cleaning surfaces contaminated with asbestos fibers.

Wet Removal Tools

Tools that apply water or other wetting agents to minimize fiber release during removal.

Sealing and Encapsulation Products

Materials used to seal or encapsulate asbestos-containing materials that are to remain in place.

Air Monitoring Equipment

Devices that measure airborne asbestos fiber levels to ensure safety standards are maintained.

Disposable Coveralls and Boot Covers

Single-use protective clothing to prevent fiber transfer outside work zones.

Sealing Tape and Adhesives

Specialized tapes for sealing seams and joints in containment barriers.

Labeling and Signage

Clear warning signs and labels for hazardous areas to ensure safety protocols are followed.

Inspection and Sampling Kits

Tools and supplies for collecting samples and inspecting asbestos removal sites.

Ventilation and Exhaust Fans

Fans used to improve air circulation and control dust during abatement activities.

Cleaning and Disinfection Supplies

Products for thorough cleaning of work areas post-abatement to remove residual fibers.

Popular Choices

Lightweight, single-use coveralls designed for protection during asbestos removal.

High-efficiency vacuum cleaners that help in cleaning asbestos-contaminated surfaces effectively.

Particulate respirators with HEPA filters to protect workers from inhaling asbestos fibers.

Durable plastic films used to create containment barriers around work zones.

Portable units that help maintain negative pressure within containment areas.

Leak-proof bags designed specifically for asbestos waste collection and transport.

Specialized tape for sealing off containment barriers and joints.

Stations for personnel and equipment decontamination to prevent fiber spread.

Instruments used to monitor airborne asbestos levels during and after removal.

Full-body suits designed for comprehensive protection during asbestos handling.

Pre-moistened wipes for cleaning surfaces and equipment to reduce fiber release.

Fans used to improve airflow and reduce dust accumulation during abatement.

Tools for collecting asbestos samples for analysis and verification.

Signs to clearly mark hazardous asbestos removal zones.

Materials used to encapsulate asbestos materials to prevent fiber release.

Asbestos abatement involves careful planning and execution, often requiring a combination of products that work together to contain, isolate, and safely dispose of asbestos materials. High-quality containment barriers and negative air pressure systems are essential for preventing fiber migration. Personal protective equipment such as respirators and protective suits provide the necessary safety for workers handling hazardous materials. Proper disposal containers and decontamination units ensure that asbestos waste is managed in compliance with regulations.

Understanding the specific needs of a project, including the type of asbestos-containing materials and the environment in which removal occurs, helps in choosing appropriate products. Safety considerations, ease of use, durability, and compliance with safety standards are critical factors to evaluate. Investing in reliable, tested equipment can facilitate a smoother abatement process, reducing risks and ensuring adherence to safety protocols. Whether undertaking a small-scale removal or a large commercial project, the right selection of products is fundamental to effective asbestos management.

Key Buying Considerations

- Regulatory compliance and safety standards adherence

- Type and extent of asbestos materials present

- Compatibility of containment and removal products

- Ease of setup and use, especially for large projects

- Durability and strength of containment barriers

- Effectiveness of negative air pressure systems

- Protection level provided by personal protective equipment

- Ease of disposal and waste management features

- Availability of decontamination and cleaning supplies

- Air monitoring capabilities and equipment accuracy

- Cost-effectiveness relative to project scope

- Portability and storage requirements of equipment

- Training and instructions provided for proper use

- Compatibility with existing safety protocols

- Environmental conditions of the work site, such as humidity and temperature