Optimal Timing for Asbestos Abatement

Asbestos abatement is most effectively performed during periods of low occupancy or when construction activities are scheduled. Typically, late spring and early fall offer favorable weather conditions for safe and efficient removal. Conducting abatement during these times minimizes disruption and ensures proper containment.

Spring and fall are ideal due to moderate weather, reducing weather-related delays and risks.

Avoiding extreme temperatures and high humidity helps maintain safety standards and material integrity.

Performing abatement during periods of low occupancy minimizes exposure risks and business disruptions.

Scheduling during planned renovations or downtime can optimize safety and efficiency.

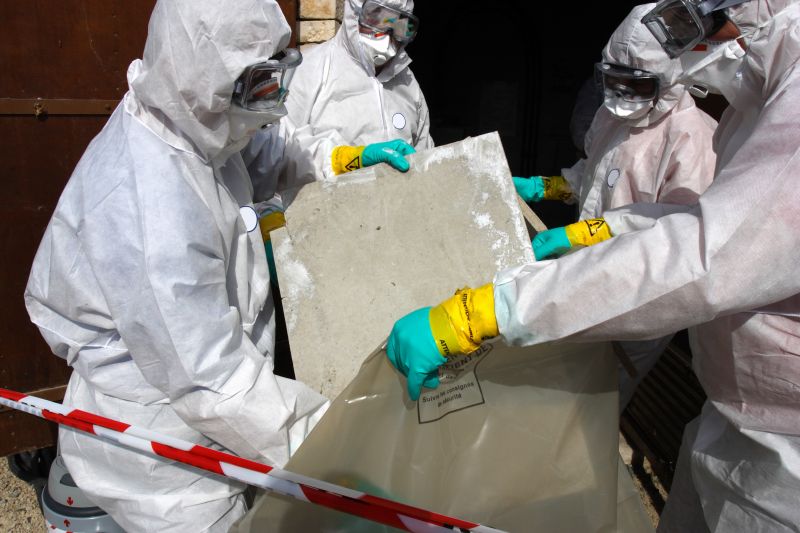

Specialized tools and containment barriers are used during removal.

Workers wear protective suits and respirators to prevent exposure.

Sealed containment zones prevent asbestos fibers from spreading.

Ways to make Asbestos Abatements work in tight or awkward layouts.

Popular materials for Asbestos Abatements and why they hold up over time.

Simple add-ons that improve Asbestos Abatements without blowing the budget.

High-end options that actually feel worth it for Asbestos Abatements.

Finishes and colors that play nicely with Asbestos Abatements.

Asbestos abatement involves the safe removal and disposal of asbestos-containing materials to prevent health hazards. Asbestos was widely used in construction for insulation, flooring, and roofing until its health risks became evident. Proper abatement is crucial to minimize airborne fibers that can cause respiratory diseases, including mesothelioma and asbestosis. According to industry data, effective removal reduces asbestos-related health issues significantly when performed by trained professionals.

Step-by-step removal with safety protocols.

Specialized containers ensure safe transport of asbestos waste.

Continuous testing ensures removal effectiveness.

Final checks confirm safety and compliance.

Little measurements that prevent headaches on Asbestos Abatements day.

A 60-second routine that keeps Asbestos Abatements looking new.

A frequent mistake in Asbestos Abatements and how to dodge it.

Small tweaks to make Asbestos Abatements safer and easier to use.

| Factor | Importance |

|---|---|

| Weather Conditions | Affects safety and scheduling |

| Occupancy Levels | Impacts timing to reduce exposure |

| Project Scope | Determines duration and complexity |

| Regulatory Deadlines | Ensures compliance and permits |

| Seasonal Accessibility | Influences equipment and personnel logistics |

Choosing the right time for asbestos abatement is essential for safety, compliance, and efficiency. Proper planning considers weather, occupancy, and regulatory requirements to ensure the process is conducted smoothly. Early planning and scheduling during optimal periods can reduce delays and costs while maintaining safety standards.

Trained personnel carefully remove asbestos materials.

Prevent fiber spread during abatement.

Ensures all asbestos fibers are removed before reopening.

Lower-waste or water-saving choices for Asbestos Abatements.

The short, realistic tool list for quality Asbestos Abatements.

Rough timing from prep to clean-up for Asbestos Abatements.

Quick checks and paperwork to keep after Asbestos Abatements.

Examples that show the impact a good Asbestos Abatements can make.

Interested parties should consider scheduling asbestos abatement during periods that align with project timelines and seasonal advantages. Proper timing enhances safety, reduces operational disruptions, and ensures compliance with all safety standards. For more information or to discuss scheduling options, contact a professional to determine the best approach for specific needs.